Omnitech Srl has started a department of "Development and implementation of interface systems between Robots - Machine tools" and other systems, in particular interfaces between robots and universal welding systems for sheet metal modules, etc.

The technologies used by our robotic welding systems are: MIG - MAG (wire welding), TIG with and without filler metal, Plasma with and without filler metal, Laser, MIG Brazing, Induction brazing, Resistance, Anti-wear backs MIG-MAG.

Our systems are able to weld different metals, in particular: Stainless steels, alloyed and high-strength steels, carbon steels, aluminum steels, titanium.

The activities carried out by the new department are:

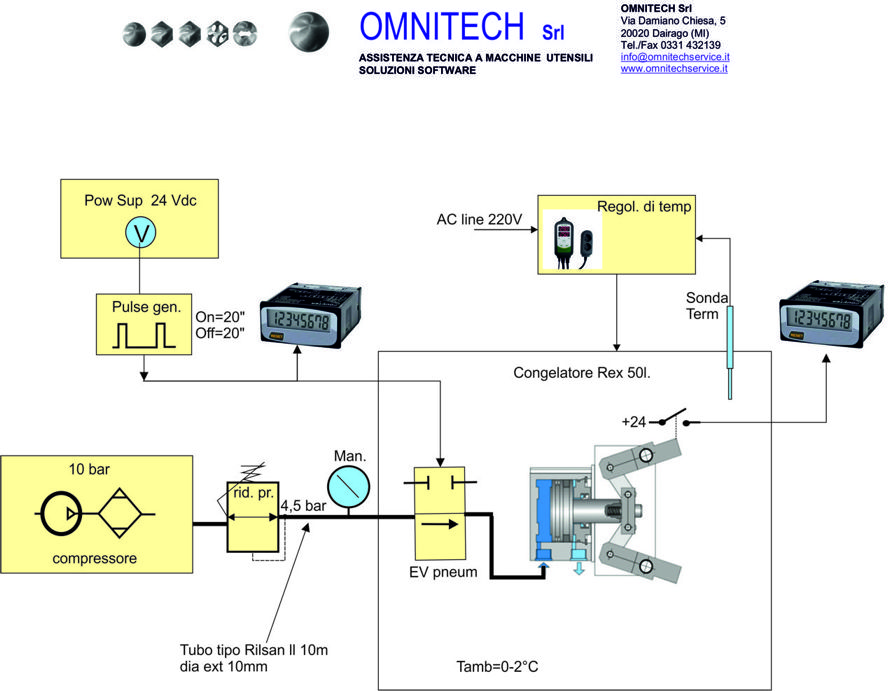

- development of H / W and S / W interfaces between the Robot and the machine tools (eg EDM) and other systems of automatic plants in the sectors of packaging, distribution, pick and place, etc.

- Machine tools always require a "servant" to carry out the work, ie a person who: prepares the machine with the appropriate tool, loads the crude to be processed, has the appropriate machining program and finally monitors the MU during processing; at the end it must disassemble the worked piece and store the tool, clean the MU and start a new cycle. All these operations, which could be carried out by a robot, require a complex interface consisting of Hardware (electronic and mechanical) and Software.